SuperChrome® :: The Best Chrome Paint Technology ::

SuperChrome® Motorcycle

SuperChrome: The Best Spray Chrome Technology

SuperChrome was invented, refined and patented in Europe. It is sold in 53 countries world wide and has become the premier spray-on chrome solution for many industries across the globe.

Upon arriving in North America, The SuperChrome Company began testing and refining the process to make SuperChrome paint even better. Engaging scientists and technologists in both Canada and the United States to test many available base coats and clear coats; they developed some unique formulations of their own. SuperChrome has developed solutions to various issues faced in the spray chrome industry.

SuperChrome offers spray-chrome solutions to the auto market, hobbyists, for movie production and set design. SuperChrome is also used in architectural and interior design industries because of its high durability, flexibility and precision application abilities.

SuperChrome has become a world leader in spray-on chrome technology and the product of choice in many fields.

Check out our DIY page for hobbyists

SuperChrome®

SuperChrome® is the future of spray chrome technology. It is durable enough for exterior applications. The three step process can be performed in any standard commercial paint booth with conventional HVLP spray gun technology.

SuperChrome® uses a new patented additive that chemically binds the base coat, the middle silver chromium coat and the final top coat - clear or tinted to form a single hard, durable OEM chrome-like finish.

SuperChrome® will adhere and cover most any substrate with a chrome-like brilliance that is beautiful, durable and cost effective. SuperChrome® has been shown to bond to these different substrates: metal, fibre glass, polystyrene, fabric, cement, plaster, ceramic, plastic, vinyl, Styrofoam, aluminium, glass, rubber, and more.

SuperChrome® is the most cost-effective product in the market today, offering brilliance, flexibility and durability superior to its competitors.

View more

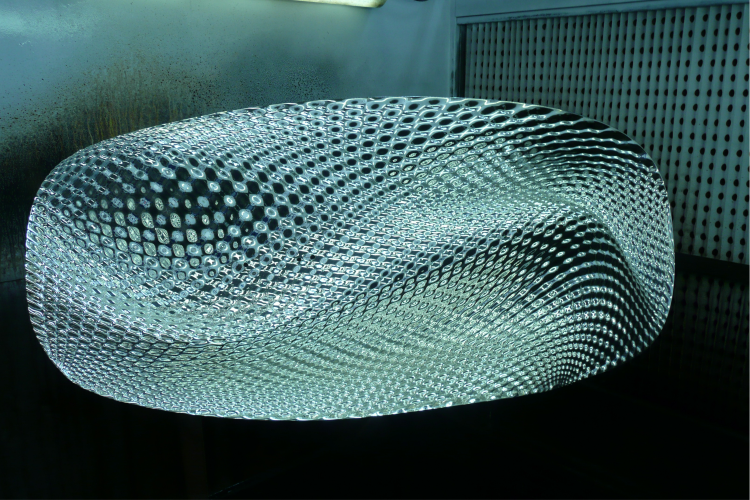

HydraChrome

Hydrographics, also known as immersion printing, water transfer printing, water transfer imaging, or cubic printing, is a method of applying printed designs to three dimensional objects. The hydrographic process can be used on metal, plastic, glass, hardwoods and various other materials.

In the process, the substrate piece to be printed is pre-treated and a base coat material is applied.

A poly vinyl alcohol film is gravure-printed with the graphic image to be transferred, and is then floated on the surface of a vat of water.

An activator chemical is sprayed on the film to dissolve it into a liquid and activate the bonding agent. The object is then lowered into the vat, through the floating ink layer, which wraps around and adheres to it.

HydraChrome follows this same process with the addition of a SuperChrome® base coat, then the inks are bonded to the SuperChrome® , and the clear or colour-tinted top-coat finishes the process, producing a unique, brilliant, eye-cathing product.